PS

Sunny, "Friend from TTE" ...............

I'm sure he'd like some more friends overseas too

Maybe someone in the English Riviera (Bournemouth) nudge nudge, wink wink

Some interesting bits and pieces you have going on for sure

| www.gt4dc.co.uk http://gt4dc.co.uk/forum/ |

|

| Project Taurus http://gt4dc.co.uk/forum/viewtopic.php?f=1&t=2908 |

Page 2 of 37 |

| Author: | two_OH_five [ Sun May 10, 2009 12:00 pm ] |

| Post subject: | |

PS Sunny, "Friend from TTE" ............... I'm sure he'd like some more friends overseas too Maybe someone in the English Riviera (Bournemouth) nudge nudge, wink wink Some interesting bits and pieces you have going on for sure |

|

| Author: | Sunny [ Sun May 10, 2009 12:07 pm ] |

| Post subject: | |

Hi, 32mm (outer diameter!) becouse i don't want a pipe that is smaller in diameter then the OEM hose, 32mm was available aluminium is the better choice, but i cannot weld it with my company's welding, and i have not the right tool to bend a alu pipe the reason why i replace the samco hose is that, when you drive in rpm's around 3500rpm's and higher if the thermostat is opened (engine is good warm) a hose will pull together, this means that the water flow is restricted up to 70%, definitely not good for a performance engine the pressure in the system is not significantly this is important if you race or rally the car where you drive the engine a lot of time or ever hard, doesn't know it about track where you only drive short....i only saw that some evo track driver have replaced the OEM radiator against a smaller core so that there is enough space for a big turbo (only track condition please!) i forgot to wrote that if i drive gently around 120-130km/h, 5th gear the water will also cool down extremely @ "Friend from TTE" was a user in the german gt4 forum (project manager engine), but is not online any more, does't know why the next idea i want to realize is to build a channel around the radiator package so that no air can pass them, but this project is not important this time greetz |

|

| Author: | TrackToyFour [ Sun May 10, 2009 12:55 pm ] |

| Post subject: | |

Hi Alex, Many thanks for the explanation, all makes sense now The Jaguar at the Silverstone FIA GT race last weekend is a good example of this. Note that they only use the Wiggins connector at the radiator end of the hard pipe. They still need a short length of flexible hose to accoodate the engine movement against the rigid mount radiator

|

|

| Author: | TrackToyFour [ Sun May 10, 2009 1:30 pm ] |

| Post subject: | |

Sunny wrote: the next idea i want to realize is to build a channel around the radiator package so that no air can pass them, but this project is not important this time

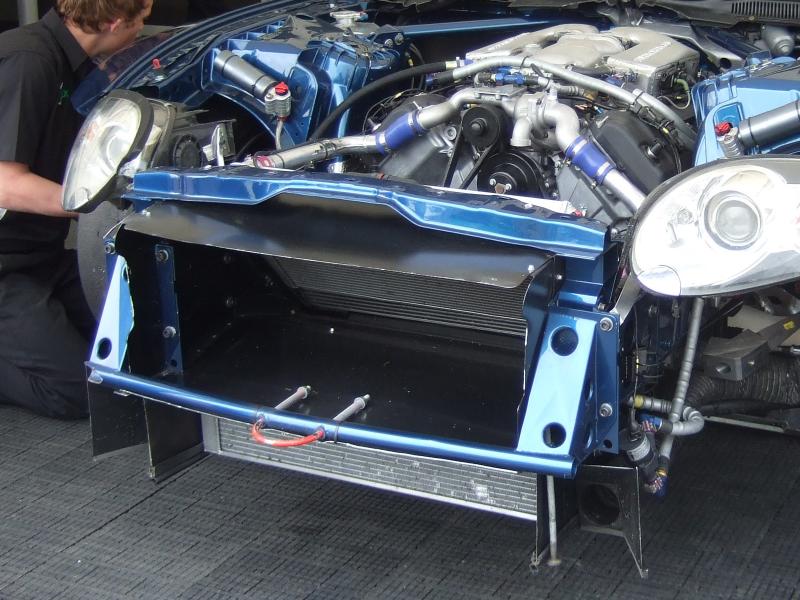

Good example of this on the Jag GT

|

|

| Author: | Sunny [ Sun May 10, 2009 4:40 pm ] |

| Post subject: | |

Hi, this two pictures are greate examples greetz |

|

| Author: | two_OH_five [ Sun May 10, 2009 9:06 pm ] |

| Post subject: | |

OOOOF Honking gurt V8, racecar Goes off for a bit of a lie down |

|

| Author: | Wolf_Tm [ Tue May 12, 2009 1:34 pm ] |

| Post subject: | |

Sunny wrote: the reason why i replace the samco hose is that, when you drive in rpm's around 3500rpm's and higher if the thermostat is opened (engine is good warm) a hose will pull together, this means that the water flow is restricted up to 70%, definitely not good for a performance engine Do you mean the rubber pipes collapse ? |

|

| Author: | Sunny [ Tue May 12, 2009 2:44 pm ] |

| Post subject: | |

Hi Wolf, yes, pull together = collapse the water flow of the pump raise with ervery rpm, but the hose don't want this greetz |

|

| Author: | Wolf_Tm [ Tue May 12, 2009 2:46 pm ] |

| Post subject: | |

Sunny wrote: Hi Wolf,

yes, pull together = collapse greetz Ok, so why did you say that water pressure inside the rubber pipes is not important ? |

|

| Author: | Sunny [ Tue May 12, 2009 2:49 pm ] |

| Post subject: | |

Hi, sorry, not important for the process i explain water pressure is important for the boiling point greetz |

|

| Author: | Wolf_Tm [ Tue May 12, 2009 2:51 pm ] |

| Post subject: | |

Sunny wrote: Hi,

sorry, not important for the process i explain water pressure is important for the boiling point greetz Sure, but I imagine pressure inside the pipes makes also them not to collapse... didn't it ?!? |

|

| Author: | Sunny [ Tue May 12, 2009 2:59 pm ] |

| Post subject: | |

Hi Wolf, if it has a effect, only a very small after i mounted the pipe i observed a great step in water cooling greetz |

|

| Author: | Wolf_Tm [ Tue May 12, 2009 3:11 pm ] |

| Post subject: | |

Sunny wrote: Hi Wolf,

if it has a effect, only a very small after i mounted the pipe i observed a great step in water cooling greetz Sunny, believe me... it's not my intention to "attack" you or your "TTE friend"... but I think "observations" are to be made ONLY in a scientific way... that is to say with ecu/computer loggings of good sensors and calculations. Many other factors enter in the play with the oil temp: water temp, egt temp, ambient temp, ambient pressure, humidity, engine load, oil type, oil contamination, etc etc. I'm saying this because it's really hard for me to believe that a change in pipes material could result in a -20 deg C. in oil temp! That is not to say I don't believe you... understand me... I trust you see this loss in temps... Cheers. |

|

| Author: | Sunny [ Tue May 12, 2009 3:22 pm ] |

| Post subject: | |

Hi, wolf i unterstand you, it is good to be suspicious this makes people to ask "why" as seen in here you will become a update when it is hot outside -> around july i hope the themp. will be stay low, but i think it will raise sorry i wrote this a bit wrong, i make only moment recordings this time, 30min racing the engine (many curves, up and down) -> peak oilthemp. 103°C, outside themp. around 25°C, 0,9bar boost to be updated greetz |

|

| Author: | Wolf_Tm [ Tue May 12, 2009 5:10 pm ] |

| Post subject: | |

Even because in WRC 3SGTE just small sections of engine water pipes are aluminum: if it was that important, I suspect they'd made them of aluminum entirelly. For example I think they used aluminum near the DP to avoid problems in unwanted contacts. And to turn far from the intake manifold to avoid breaking it.

|

|

| Page 2 of 37 | All times are UTC + 1 hour |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|